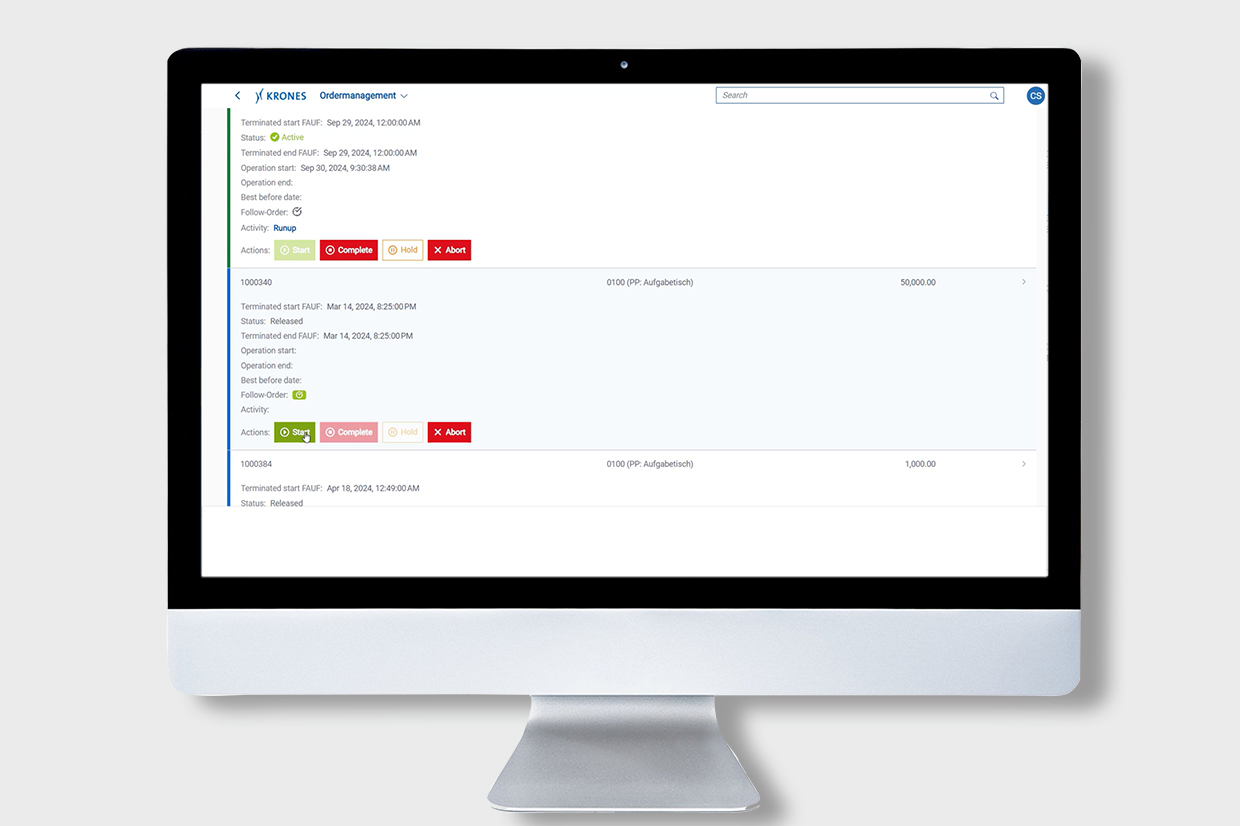

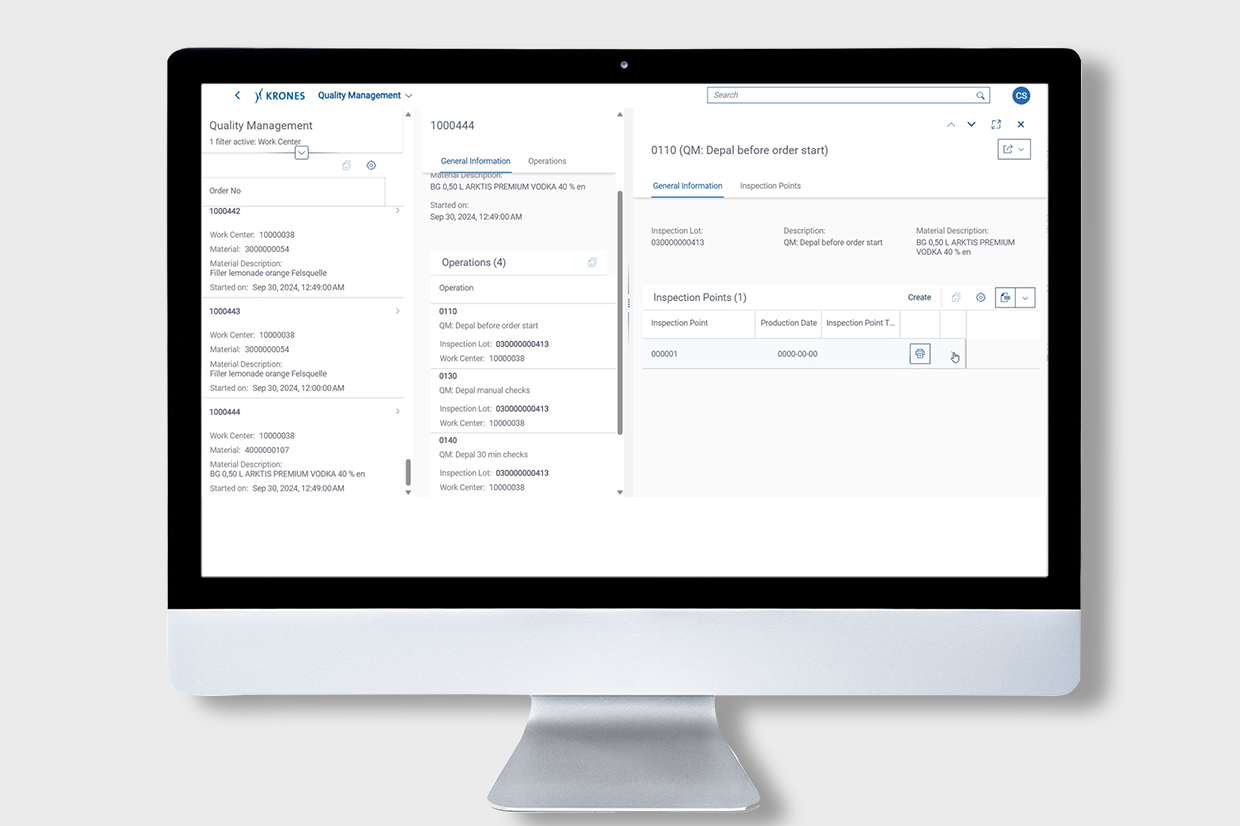

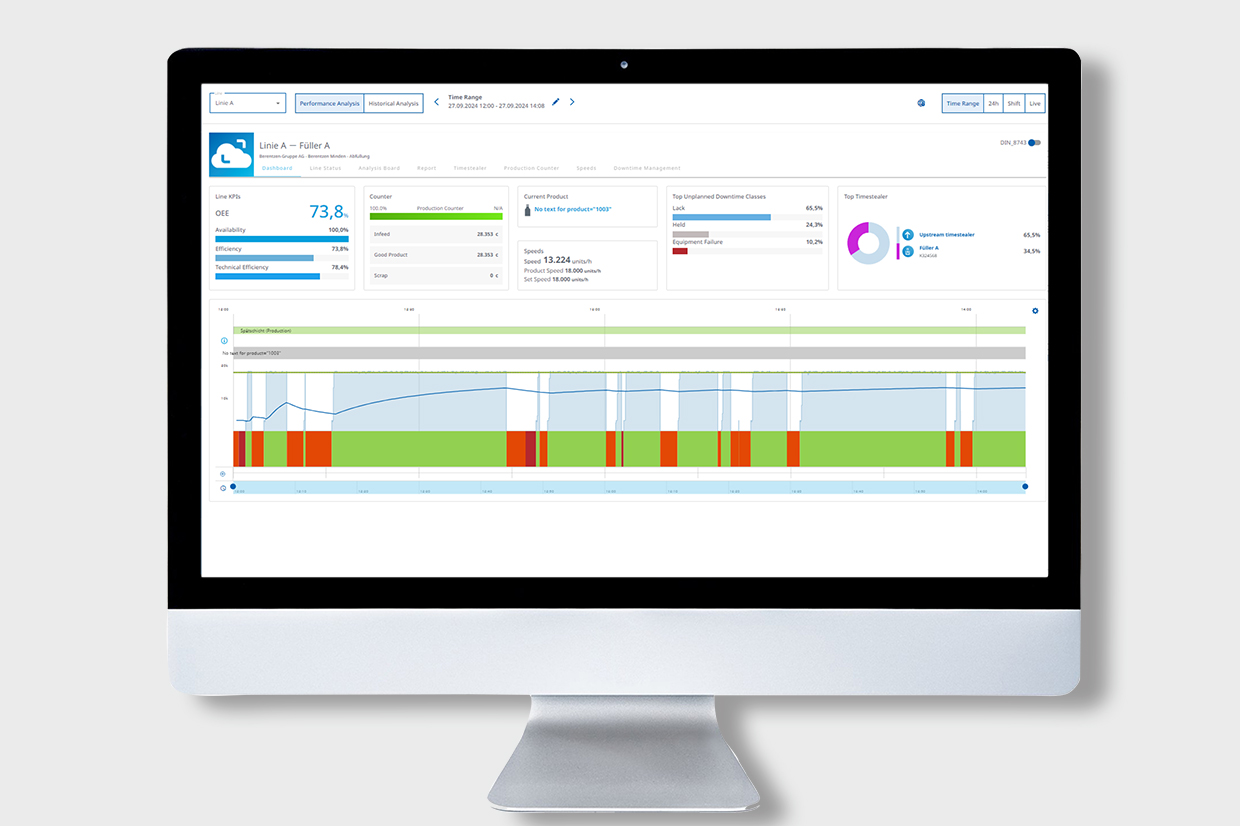

From a production order right through to quality control testing – every manufacturing company has information that needs to be documented. At the Berentzen Group’s Minden plant, this was, until recently, mostly done on paper – that is, by hand. As a result, fulfilling a production order entailed a lot of communication and time, in addition to what it took to actually get the job done. Adding to the challenge was the fact that production-relevant information was often located in different places within the various documents. All in all, it was hard to keep a clear overview. But precisely that is essential to ensuring that processes run efficiently and production and management are optimally aligned.

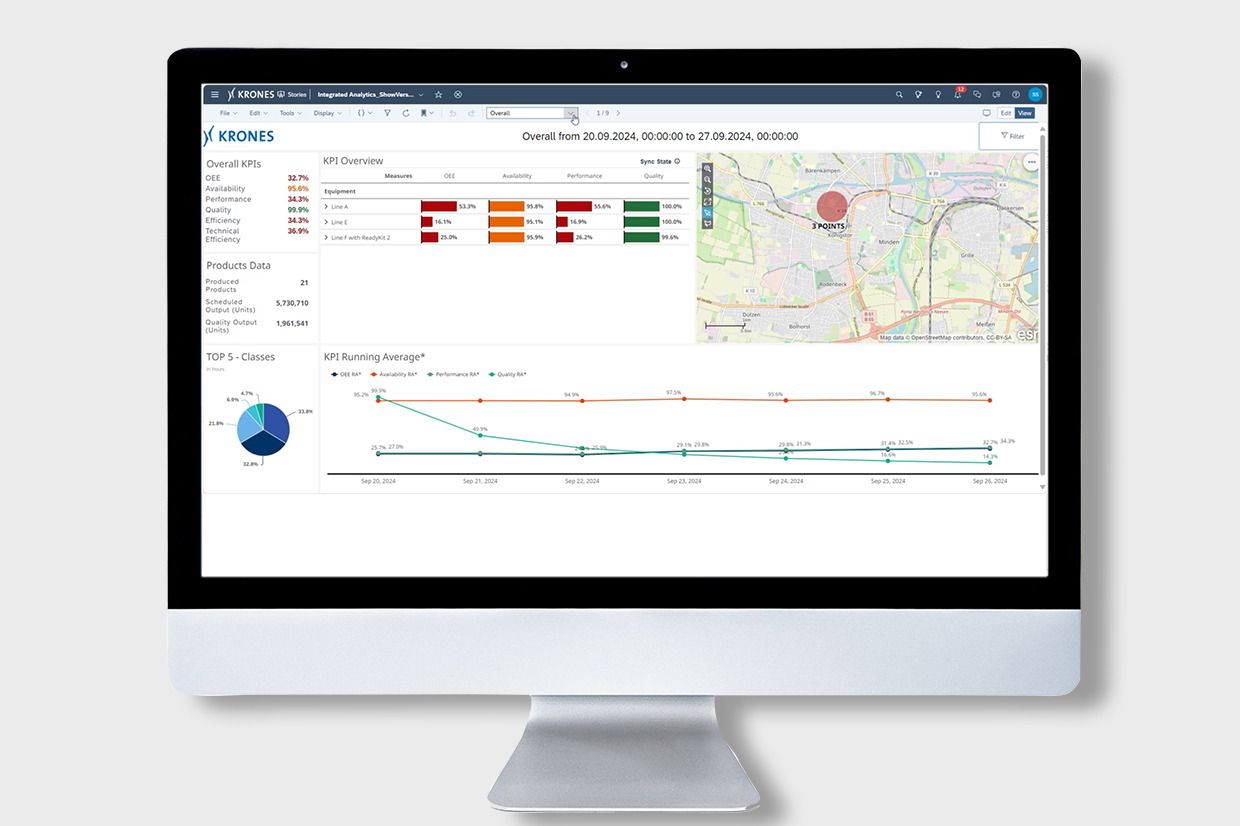

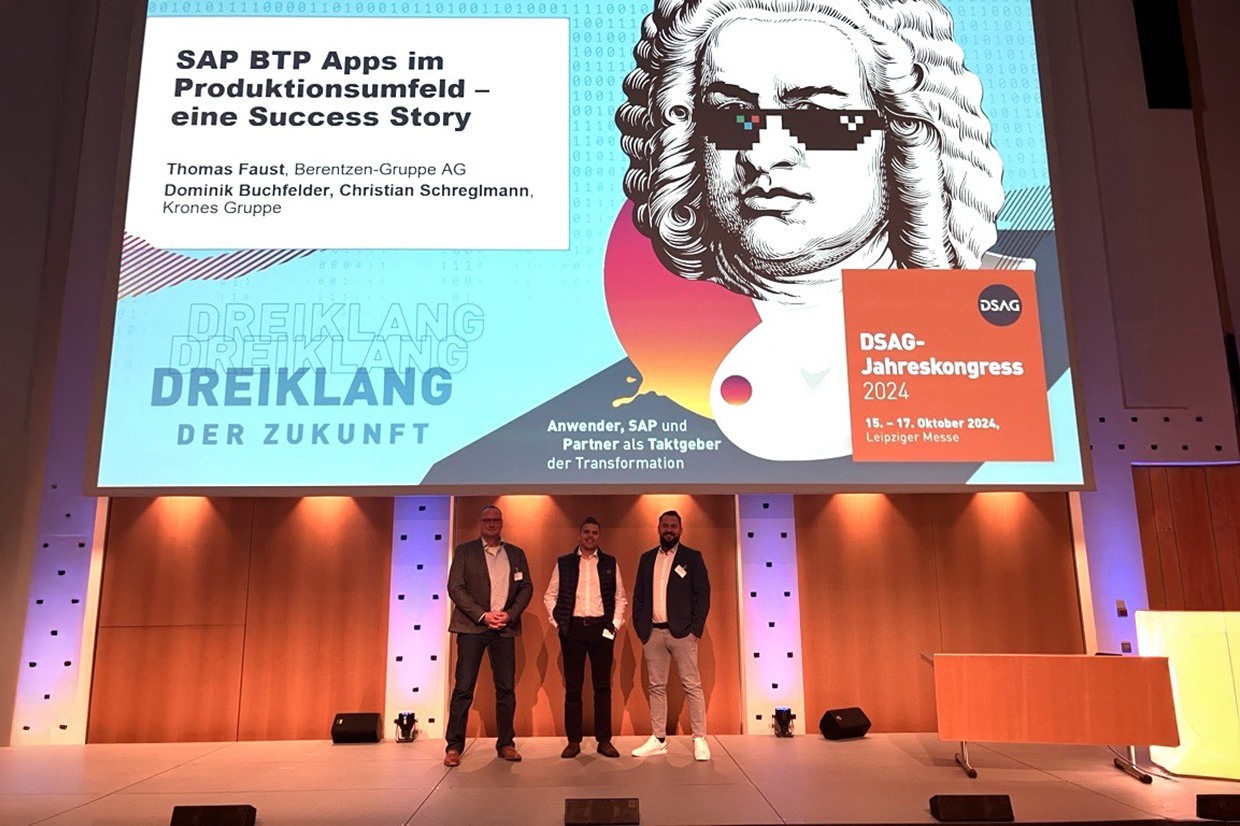

In other words, it was time for a change. And so, the Berentzen Group decided to fundamentally restructure their production and administrative processes. In August 2023, in collaboration with Krones, they kicked off a comprehensive digital transformation project at Minden under the name “Mehrblick”. “Thanks to their expertise and years of experience in the beverage industry, Krones was already familiar with many of our processes. The way they approached the project was exemplary and really just super. We never thought of Krones as a service provider but as part of the project team,” says Christian Redeker, Technical Manager at the Berentzen Group.