Krones plant engineering - shaping a successful future together

Sharing responsibility for tomorrow

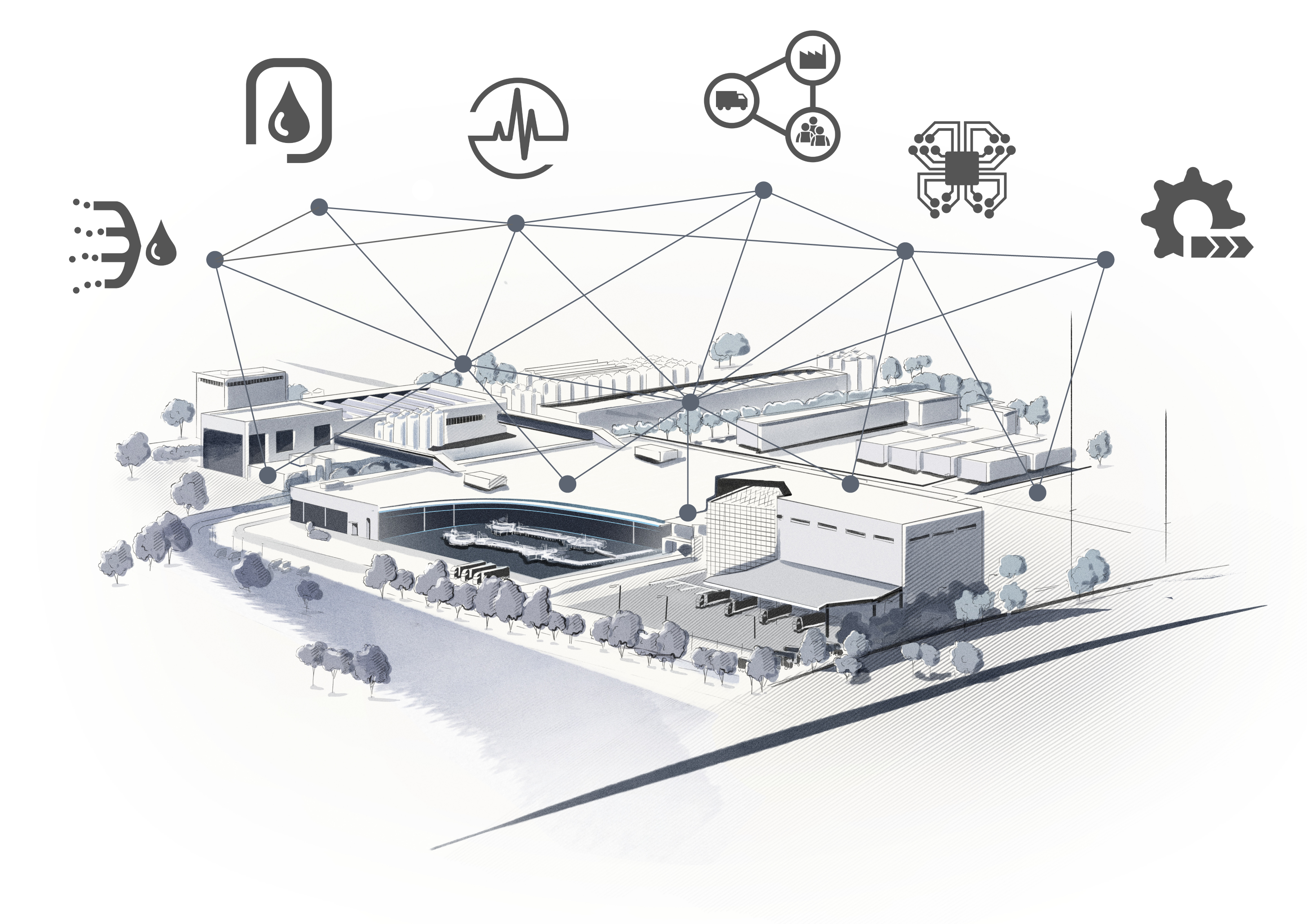

The most efficient and customised production possible along the entire value chain is at the centre of our planning. With our expertise, we generate decisive added values for you.

Everything from a single source

-

Independent advice for the entire factory

-

Feasibility and concept studies for new buildings and factory structure planning

-

Master planning of the production facility (overall factory layout)

-

Improvement in line operation (production, logistics, sustainability)

-

Concepts for energy and media supply

-

Functional tender documents

-

Consultancy and project coordination during the implementation phase

What makes us special - our unique selling point

Overall expertise in one team

Not only do we combine all of our expertise in one team, we also have full access to the worldwide Krones network – and therefore the global expertise of the Krones Group.

With a holistic approach, a broad range of services and a global Krones presence, we are always close to our customers and offer the entire planning from a single source.

A holistic approach

Regardless of the type of product we are able to take a holistic view of a complex beverage or food factory.

Targeted focus on individual areas of the company is also possible for selective optimisation.

We offer services from a single source in order to reduce interfaces and maximise efficiency in planning projects.

Partnership to create the perfect production facility

Together, we will develop a modern, efficient and competitive factory for your new building. With tailor-made solutions which are economically optimised, technologically sophisticated and sustainably designed to meet your current requirements precisely and can be expanded to meet future needs.

We develop individual solutions for existing production facilities to expand, restructure or realign them in a targeted manner, entirely in line with your needs and goals.

A step-by-step implementation ensures continuous production and at the same time creates the conditions for economic growth.

Sustainability and digitalization are leading to a significant change in the design of factories

Saving costs by reducing the energy and material consumption as well as waste generation

-

Reduction of CO2 emissions: along the entire value chain

-

Zero-waste concept: packaging materials, product, media, energies...

-

Sustainable packaging solutions: rPET, carton instead of film, weight optimisation

-

Cloud-based energy and media reports: Transparency, efficiency, key data, contextual information

Reducing water requirements to protect local water resources and prevent water losses

-

Mature water saving potentials: Hot filling, CIP with recovery tank, closed cooling tower circuit ...

-

Separation of differently contaminated streams: Waste water with BOD and COD, RO concentrate, rainwater ...

-

Waste water avoidance and recovery: Optimised production planning, reverse osmosis, waste water treatment ...

Reducing operating costs through optimised production solutions and automated processes

-

Master layout planning: Site comparison, reduced space requirements, flexibility of expandability, material flow I arrangement model, BIM planning ...

-

Automation and digitalization: IT architecture, smart factory design, appropriate level of automation, ERP landscape, cyber security ...

-

"Lights-out" production: Autonomous raw and finished goods handling with robots, AGVs, digital ecosystem, live monitoring ...

Benefits

-

Integrated consideration – the entire planning from a single source

-

Customised plant engineering – tailored to your needs

-

Focus on the defined goal – independent consultation

-

Overall planning – efficient and quick project proces

-

Increased productivity for the production site

-

Reduction of the investment and operating costs (CAPEX and OPEX)

-

Forward-looking, future-proof engineering

With holistic energy concepts and onsite audits, the resource management of energy and media consumptions and digital solutions, we highlight all relevant topics that offer you lasting added value.