Polyolefin recycling solutions: From PO containers to flakes

Sustainability and profitability: our contribution to a circular economy

When one compares the recycling of containers made of polyolefins (PO) and those made out of PET, PO containers present numerous challenges: On the one hand, they are lighter than water which calls for a different procedural approach. On the other, the containers can take on the odour of the products they contain. Krones approaches all of these issues with a recycling technology which has been modified to precisely suit the processing of polyolefins.

At a glance

- Recycling of PO containers into flakes

- MetaPure W-PO washing module

- Intensive pre-washing

- Hot post-washing for an excelling washing result

- Thanks to our co-operation with partners: Krones can also supply complete solutions with systems for the subsequent further processing of the PO flakes

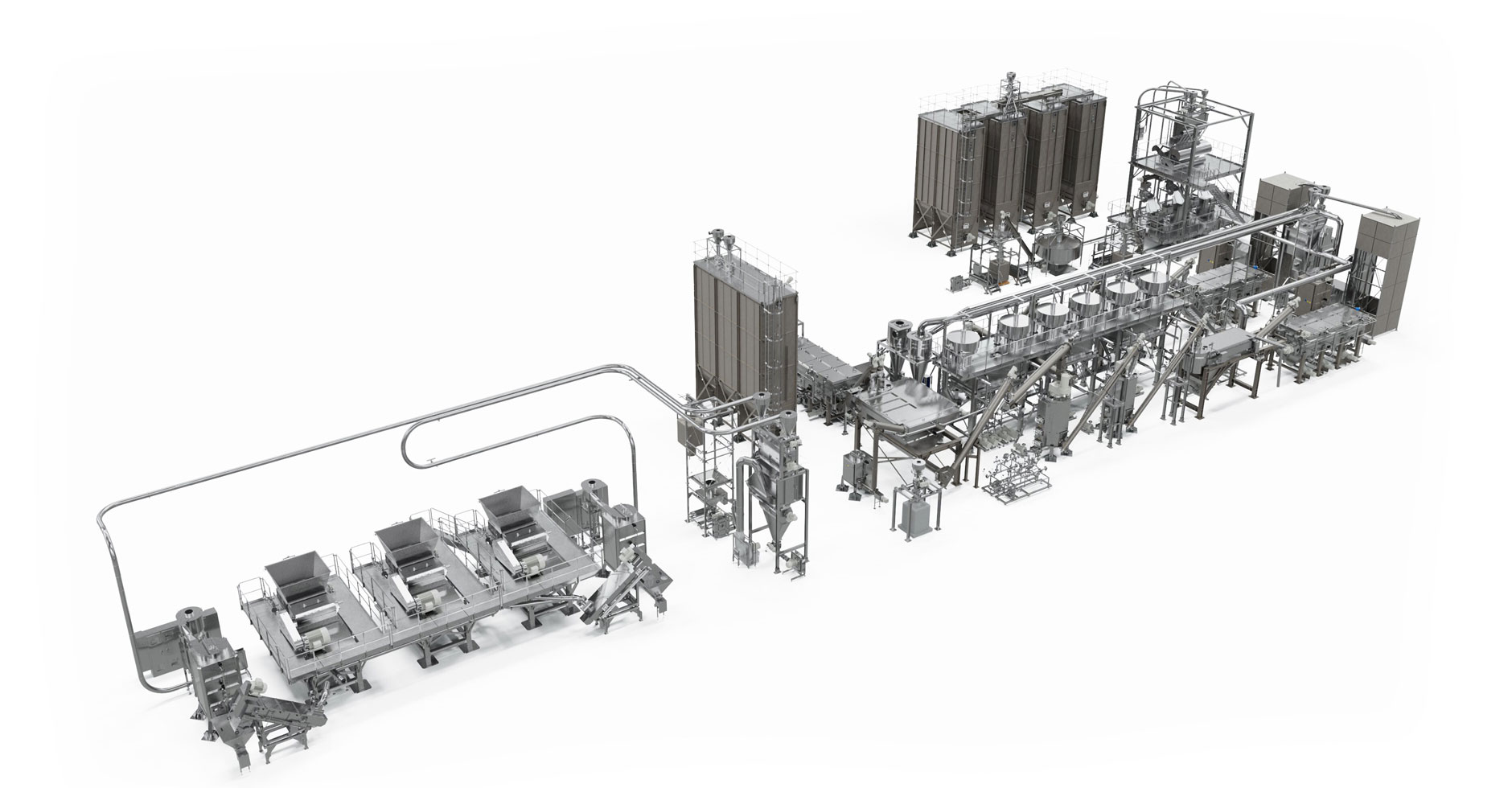

Two system types for PO recycling

| MetaPure (complete system) | MetaPure W-PO |

|---|---|

| Applications | |

Recycling of containers

|

Recycling of containers to form PO flakes for non-food use |

| Output | |

| 1,000 kg/h to 4,500 kg/h | 1,000 kg/h to 4,500 kg/h* |

| Space requirement | |

| 600 – 3,500 m2 | 250 – 1,000 m2 |

*Several modules can be combined with each other in order to achieve higher outputs.

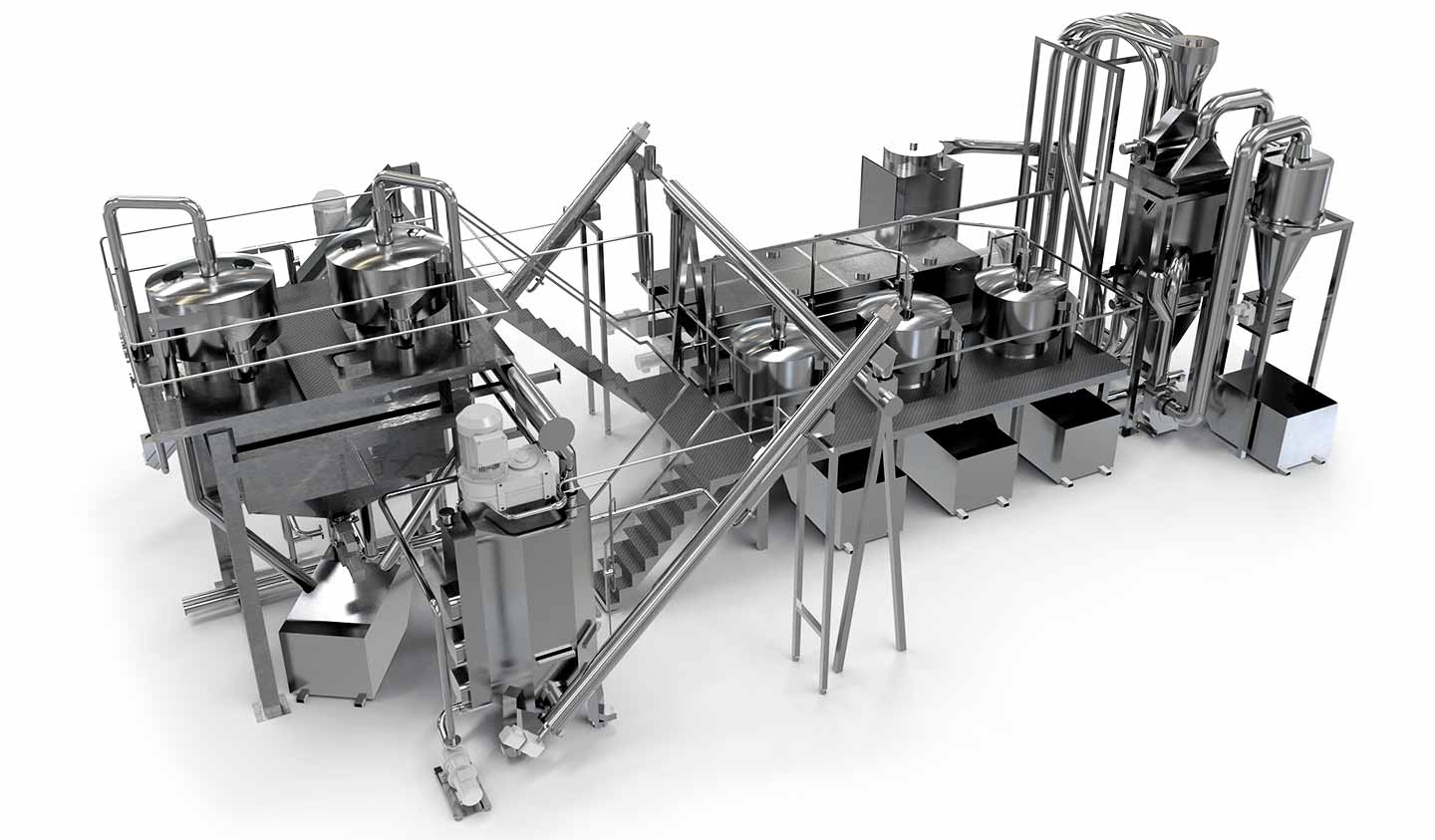

MetaPure W-PO –upcycling instead of downcycling

In the MetaPure W-PO, well proven individual units were adapted to suit conditions specific to PO while keeping the process-related attributes of the Krones washing technology unchanged.

Excellent cleaning results with the Krones washing technology

- Pre-cleaning sequences (optional)

- Caustic cleaning with caustic renewal

- Multi-stage post-washer

- Drying

- Automatic waste management system reduces the operator’s workload (optional)

- Reliable removal of the sinking fraction and labels

The Krones washing process with pre-treatment, caustic washing and hot washing ensures clean flakes which can be ideally used for the manufacture of high-quality applications (fibre, film, injection moulding).

Your benefits

- Gentle treatment of the material as the units operate with a slow rotation

- Reliable removal of dirt, organic residues and adhesives using a caustic washer

- Less cleaning and more safety for the line operators thanks to the clean design and automatic waste management system

- Possibility to reuse the process water with the integrated water cascade

- Very good washing results achieved with a hot post-washing process

- Reliable removal of the sinking fraction and labels

- Constant concentration and low consumption of caustic, additives and defoamers thanks to the automatic dosing equipment

- Robust construction and design of many parts in stainless steel to protect your investment

Our complete-system expertise – Krones as a turnkey supplier and integrator

Complete recycling plant from a single source: Factory planning, project management and recycling expertise