Mount Fuji is one of the most recognizable symbols of Japan. The 3,776-meter peak is the country’s tallest and famous for its graceful cone shape. Fuji is venerated as a stairway to heaven and the dwelling place of deities and ancestors.

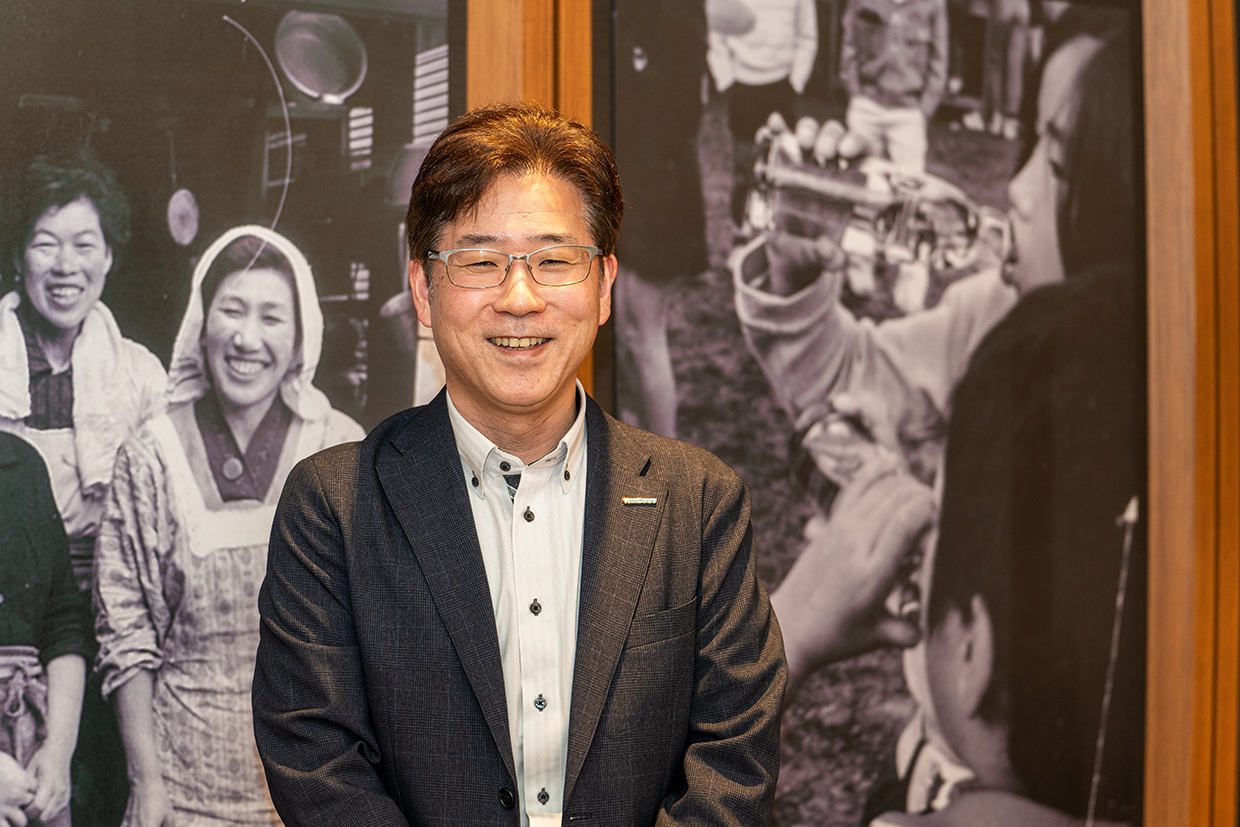

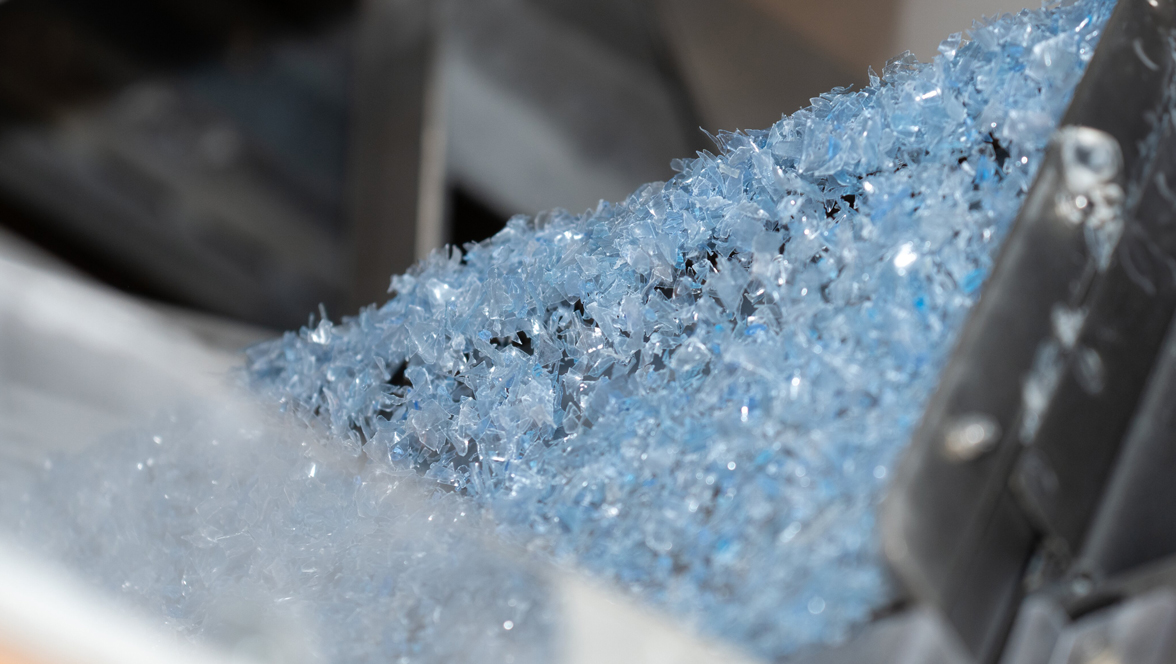

And it is here, right at its base, that Tomomasu has built its new water bottling plant. The Japanese beverage company could hardly have chosen a more culturally significant site for filling its sparkling water. After all, Japan’s iconic mountain has been providing people with safe drinking water through a vast network of groundwater and freshwater springs for thousands of years. Rain and snowmelt slowly flow through a series of basalt layers, picking up natural minerals along the way. Besides the water’s outstanding quality, the site’s close proximity to Tokyo – less than one hundred kilometers – was another reason for choosing this location. After all, the company has a great task: to supply the world’s biggest city with sparkling water!