For 15 years, the partnership with Krones has been vital to Nu-Pure's growth. It began with a compact line with equipment from Kosme and evolved into a strategic collaboration with the Krones Group, characterised by trust and loyalty.

Founded in 2005 as a small family business, Nu-Pure’s mission has been to provide healthy hydration with a commitment to deliver exceptional quality, service and value for the Australian beverage market. Fast-forward to 2024, and Nu-Pure has expanded significantly, accelerating their market growth opportunities. Now, they’ve opted for a brand-new ErgoBloc L which will catapult their production to new high-speed records.

Breaking new ground with the ErgoBloc L

In January 2024, Nu-Pure ordered a groundbreaking 100,000-bottles-per-hour (bph) line. Its centrepiece: the high-speed version of the ErgoBloc L – the first of its kind in Australia and the Asia-Pacific region. This milestone represents the culmination of years of collaboration and mutual growth.

Nu-Pure’s decision was a logical consequence when looking at their core values: Their commitment to manufacturing efficiency and providing high-quality beverages for nearly 27 million Australians has driven their demand for state-of-the-art equipment. And since the product portfolio is primarily 600-millilitre PET bottles, it is only logical to invest in a dedicated line for exactly this bottle size which will perfectly fit alongside an existing 60,000 bph PET line.

A business case for growth

The decision to purchase a 100,000-bph line was not made lightly. Initial discussions considered speeds of 60,000 to 72,000 bottles per hour, but a larger line emerged as the best option for performance and efficiency.

This high-speed line aligns with Nu-Pure's vision of maximising efficiency and achieving economies of scale: In December 2023, the company celebrated a major milestone – producing one billion bottles in a single year, most of which were filled using Krones equipment. After thorough evaluation, Krones was again selected as the supplier, solidifying their leadership in the industry with this ErgoBloc technology, now for the first time breaking the 100,000 mark.

When it comes to high-speed equipment, Krones offers unmatched turnkey solutions that seamlessly integrate innovation, reliability, and efficiency. Sid RaghuNational Engineering Manager, Nu-Pure Beverages

The success of this project hinges on a strong partnership between Nu-Pure and Krones, founded on trust and mutual respect, as Sid Raghu, National Engineering Manager from Nu-Pure underlines: “Our 15-year partnership with Krones has been instrumental to our success and growth in the Australian beverage market. When it comes to high-speed equipment, Krones offers unmatched turnkey solutions that seamlessly integrate innovation, reliability, and efficiency. Their ErgoBloc L technology and exceptional support services consistently exceed expectations, making them a trusted partner in delivering our vision for quality and sustainability.”

Looking ahead

By September 2025, the new line will be fully operational, greatly increasing Nu-Pure's production capacity to meet rising demand. This marks the seventh Krones line for Nu-Pure, showcasing their journey from a compact system to high-speed production.

How to successfully fill 100,000 bph

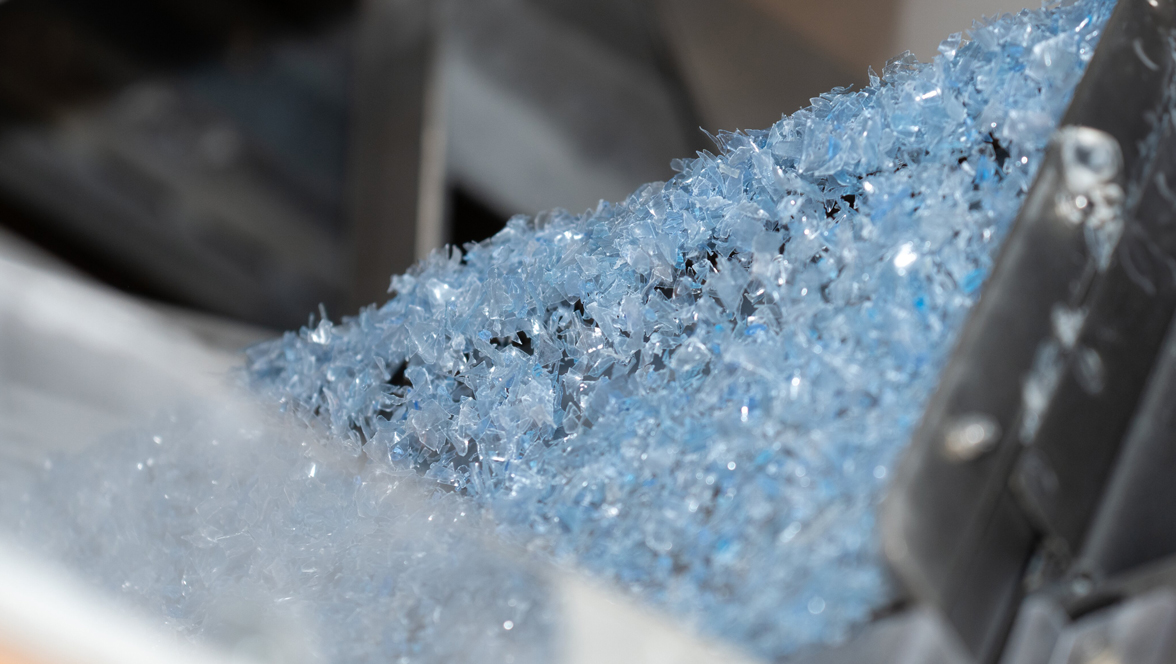

Nu-Pure's version of the ErgoBloc L is based on a dual-filler system connected to a single blow-moulder. This fully integrated solution combines stretch blow-moulding, labelling, filling, and capping into one efficient process. Nu-Pure’s version of the block is designed to fill 600-millilitre still water bottles.

Key components of the line:

- PET-View: integrated preform inspection for real-time quality control

- Contifeed: automated preform infeed

- ErgoBloc L: wet-end block comprising a stretch blow-moulder, labeller and filler

- Two Checkmat units: inspection systems for precise quality assurance (checking fill level, caps and labels)

- Ergomodul: labeller with two multiple-reel storage magazines

- Variopac Pro FS: highly flexible packer for shrink packs

- Modulpal Pro: palletiser for streamlined end-of-the-line operations

- VarioClean: CIP system for ensuring optimal cleaning and hygiene