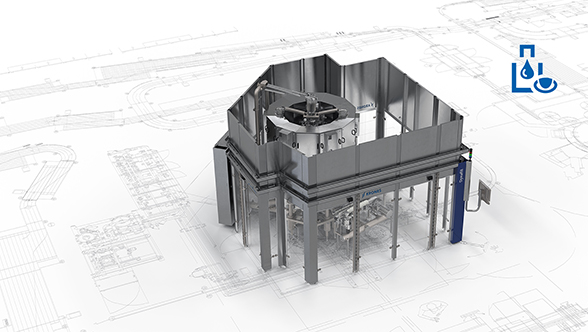

“We need a new line that can fill more bottles per hour – but on the same footprint as the old line. Can you help us with that?” Krones wouldn’t be Krones if we couldn’t come up with a good solution to this problem! We’ve got numerous block concepts – for cans and PET containers as well as for aseptic filling in particular – that allow beverage manufacturers to operate successfully in tight quarters. The latest addition to our block portfolio is designed specifically for breweries that fill their beer into glass bottles. It addresses two of the major concerns in the sector, delivering a solution for brewers who have limited space available and, at the same time, providing filling technology that sets the current industry standard for both engineering and energy efficiency.

It’s called the Dynafill Bloc FL and comprises a Dynafill filler and a labeler such as an Ergomodul with cold-glue labeling stations. What makes this block ingenious is that the two machines aren’t connected in the usual way, through multiple transfer worms, but instead by a single, pitch-adjusting starwheel. This starwheel can even out different machine pitches (from 87 to as much as 126 millimeters in both directions), allowing the filler and labeler to be set up as a block-synchronized unit.