Focus on returnables

At the company's headquarters in Ebersburg-Weyhers near Fulda, there are four filling lines, two of which are for returnable glass and one each for returnable PET and non-returnable PET. Together, they fill as many as 145,000 bottles per hour. The focus is on returnables, which make up more than 80 percent of production – and some 50 percent of that is glass.

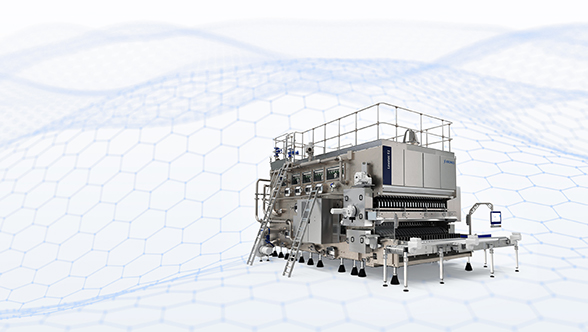

RhönSprudel recognized the strong trend towards glass packaging early on and decided in 2019 to replace an existing returnable-PET line with a new glass line. Initially, RhönSprudel awarded Krones the contract for a palletizing system that could also be used for the existing glass line. Because the plant is situated on a slope, there are warehouses for filled and packaged products on two levels, which can be supplied from either level as logistics require. Thus, the existing line can use both palletizing systems – the new one on the upper level and the old one below.

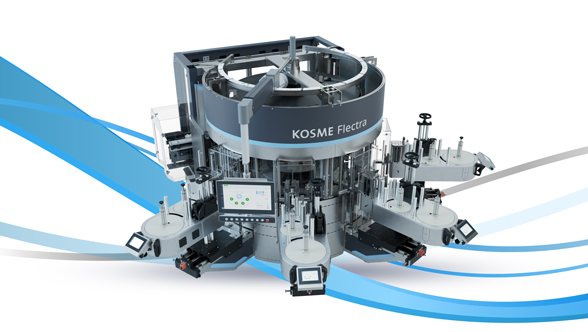

The company has since made something of a tradition of working with Krones: In 2015, RhönSprudel had Krones install a filler for the first time, and all of the labelers in the plant are made by Krones. "After our positive experience with the palletizing system, we wanted to invest in a turnkey concept – and decided to award the contract for the filling line to Krones as well. We expect that to yield synergies," explains plant manager Michael Breidung.

After our positive experience with the palletizing system, we wanted to invest in a turnkey concept – and decided to award the contract for the filling line to Krones as well. We expect that to yield synergies.

Michael BreidungPlant manager at RhönSprudel

Michael BreidungPlant manager at RhönSprudel