Code Red is the name of an energy drink which is very well-known and really popular in Saudi Arabia. It is produced by Alesayi Beverage Co. Ltd., a company accounting for an impressive share of 65 percent for energy drinks in its home market. Alesayi also fills many more beverages, mainly soft drinks into cans, water into PET bottles, and juices into cartons. Its headquarter is located in Jeddah, the country’s most important port on the Red Sea. Alesayi exports its drinks to various nations, chiefly to the Gulf states, but also to countries in North America and Australia.

Four new lines will speed up filling for a wide-ranging drinks portfolio at the Saudi Arabian beverage producer Alesayi Beverage Co. Ltd. Krones will supply the equipment for various container types: glass, PET, and can.

Expanding operations with Krones technology

Up till now, the company has produced its drinks in a plant measuring 73,000 square meters. In 2024, Alesayi completed the construction of a mega factory spanning 126,000 square meters. This state-of-the-art facility can accommodate up to 22 production lines and is designed to produce all types of beverages under one roof, including carbonated soft drinks (CSD), still water, sparkling water, juice, dairy, and ready-to-drink (RTD) coffee, as well as some functional drinks in different packaging formats. For this expansion, Alesayi puts its trust mainly in Krones technology. Orders for a total of four new lines have been placed, including equipment for the processing part as well as injection-molding machines.

At Alesayi Beverage Company, our commitment to innovation and excellence drives us to partner with industry leaders like Krones. This investment is a key step in our vision to expand globally and solidify our position as the most trusted co-manufacturing partner in the GCC. With cutting-edge technology and world-class production capabilities, we are setting new benchmarks for quality and efficiency in the beverage industry.

Sheikh Mohammed AlesayiCEO

Sheikh Mohammed AlesayiCEO

Project Overview

Location: Jeddah, Saudi Arabia

Commissioning: Started in June 2024

Scope:

- Glass line for Alesayi’s entire beverage portfolio (45,000 containers per hour)

- PET line with Contiform Bloc BF for CSDs (50,000 containers per hour)

- PET line with ErgoBloc L for water (100,000 containers per hour)

- Canning line for CSD as well as iced coffee and milk products (50,000 containers per hour)

- Krones syrup room for CSDs and juice-based products

- Hydronomic water treatment system

- Four injection-molding machines from Netstal for preforms and closures

The highlights: maximum efficiency and flexibility

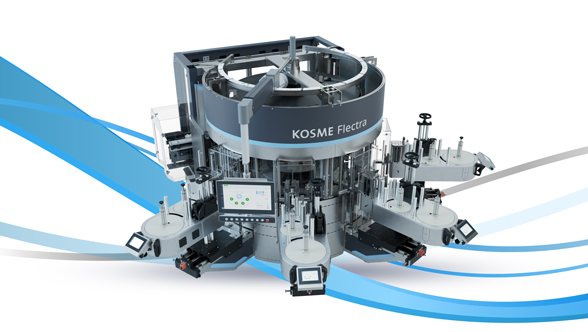

The new plant will serve Alesayi not only to process its own products but also to contract-fill and pack drinks for other beverage companies. That calls for a maximum level of flexibility, especially in the glass line. What’s impressive about this line is not so much its speed of 45,000 containers per hour but the wide range of options it provides. It can be used for both hot- and cold-filling and process a broad product spectrum, from water and fruit juices with chunks right through to milk-based mixed drinks.

Flexibility is also the watchword for dressing the containers, which is handled by four Sleevematic labellers and one Ergomodul modularised labeller. As implied by their name, the Sleevematic machines dress the glass containers in flexible film sleeves that fit snugly around different container shapes and therefore permit striking container decoration. A significant advantage if, like Alesayi, you are contract-bottling drinks for other producers. The containers are packed on two Variopac Pro machines which can put them in wrap-around cartons or on trays which are then film-wrapped.

Investing in state-of-the-art technology is crucial for our growth. By integrating Krones’ advanced solutions, we are reinforcing our position as a leading beverage manufacturer in the region, optimizing efficiency while maintaining the highest quality standards. Ali Alrajhi General Manager

High-speed PET filling

Besides the glass line, Alesayi’s order also includes two PET lines. One of these fills carbonated soft drinks at a speed of 50,000 containers per hour. The other one is a real highlight, not only for Alesayi, but also for Krones: This line features a high-speed version of the ErgoBloc L, which is the first of its kind to be installed in the Middle East and Africa.

This system is rated at 100,000 containers per hour and synchronizes the stretch blow-molder, labeller, and filler in a single block. Since it fills only one product – water – speed is the top priority here. The ErgoBloc L features two Modulfill Dual filler carousels arranged in parallel that are instrumental in achieving this magic output. One MouldXpress Robot in each line ensures faster format change-overs.

Managing the installation and commissioning of these advanced production lines has been an exciting challenge. The collaboration between Alesayi and Krones ensures that we integrate cutting-edge technology seamlessly, optimizing our operational efficiency and setting new industry benchmarks. Eng. Tomasz GawronskiProject Manager

Complete-coverage digitalization

In order to secure a technological lead over its competitors in the years ahead, Alesayi places great importance on implementing complete-coverage digitalization in its production plant. For this reason, many of the digital solutions from Krones will be integrated. All lines, systems, and materials logistics will be geared to ensuring maximally efficient operation. Key elements here include software for machine-downtime management and materials management, plus maintenance and production planning systems: These digital modules pinpoint specific potential for improvement and savings, enabling Alesayi to offer its customers tailor-made, effective filling, labelling, and packing services.

Alesayi relies mainly on the modules Line Management and Line Diagnostics. While the first serves to plan production on and set parameters for the lines to optimum effect, the second one – as implied by its name – uses the data gathered in the line to pinpoint areas in need of improvement and maximize efficiency. That aspect is of crucial importance for a company offering contract-filling services.

Digitalization and automation are at the core of our new facility. Krones’ innovative systems will enable us to achieve unparalleled efficiency in production, ensuring seamless operations from filling to packaging, and ultimately delivering superior products to our customers. Eng. Khaled ZedanHead of Operations

With this extensive investment in technology and innovation, Alesayi Beverage Company is setting new benchmarks in the beverage industry, ensuring efficiency, flexibility, and sustainability in its operations.

About Alesayi

Alesayi Beverage is not only a leading beverage manufacturer in Saudi Arabia but also one of the most trusted co-manufacturing companies in the GCC (Gulf Cooperation Council, comprising the following countries: Saudi Arabia, Kuwait, Oman, Qatar, Bahrain, and the United Arab Emirates). With a strong focus on contract packaging, the company is rapidly expanding its global presence, offering world-class production capabilities to international partners.