Probe filler for filling carbonated and non-carbonated water into glass bottles

The intelligent probe system

- Precise determination of fill quantity with a probe

- Perfect flow characteristics through two filling speeds

- Turbulence-free switching between speeds thanks to diaphragm valve technology

- Low-foam filling via swirl insert in the valve

- Closed CIP circuit

- Hygienic design

- Electropneumatically controlled filling valve functions

Field of applications

- Filling of both carbonated and non-carbonated water into glass containers, with and without conductivity

Output

- Up to 78,000 containers per hour

HES = Height filling system, Electronic fill height measuring, Short tube

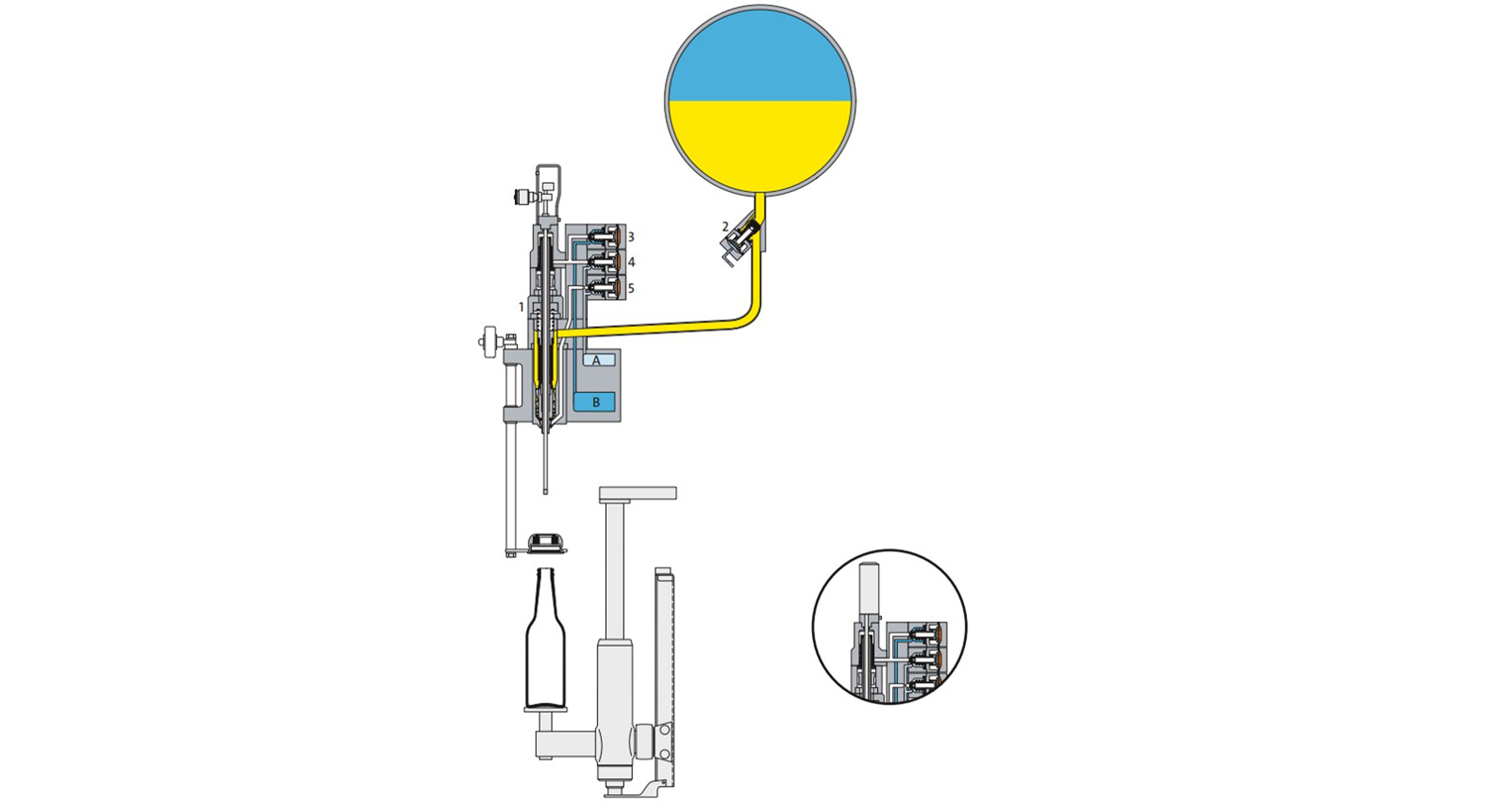

Functional principle of the valve

The glass bottle is pressed on first. The filling process will start as soon as the same pressure prevails in the ring bowl and the bottle. Two different filling speeds guarantee optimum flow. The valve closes if the liquid flowing in touches the probe mounted on the filling tube. After a settling phase, the pressure in the head space of the glass bottle is reduced via a snifting valve and the filled product exits the machine.

Conductivity > 50 µS/cm

Viscosity < 10 mPa·s

Pulp ≤ 0.4 mm/proportional < 10 %

Fibres 1 x 5 mm/proportional < 5 %

Option: Automatic probe adjustment

Ring bowl; Smaller pitch circles with central product tank

Pressurisation channel

Snifting channel

Snifting valve

Return gas and snifting valve (multi-chamber operation)

Pressurisation and return gas valve

Switching valve fast/slow

Control cylinder for liquid valve

Benefits to You

Foamless filling

- Use of swirl inserts at the filling valve outlet

Maximum filling accuracy

- Krones probe technology

- Turbulence-free change between two filling speeds through the use of membrane technology

Hygienic design

- No installed parts in the tubular ring bowl

- Press-on cam in drip-proof design

- Vacuum pump integrated in the CIP circuit

- Height-adjustable splinter washout system

- Oil-free lift cylinders

- Self-draining surfaces

- Clean pneumatic components hosing and electrical wiring

High filling stability

- Separation of the pressurisation channel and the snifting channel

- Absolutely dry pressurisation without any aerosol carry-over

Precision and long service life

- Use of special pneumatic components with a significantly higher life cycle than the one of conventional switching valves

Perfect harmony between the pneumatic components and the electronic components

- All processes 100 percent reproducible: no additional installations (e.g. pressure transducer with corresponding electronics) required

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events