For foaming products with particles

Two-channel valves with infinitely variable speed control system

Range of applications

- Products with

- Particles up to 10 x 10 x 10 millimetres

- Fibres up to 2 x 15 mm

Technical features

- Non-contact full-jet filling

- Two separate lines for liquid ingredients and particles

- Particles are dosed directly into the filling valve

- Infinitely variable filling speed

- Product feed from above via a sliding ring manifold

- Sterilisation with steam

- Dosing unit can be switched off

- Measurement of the fill quantity during particle dosing: Inductive flow meter measures the liquid product displaced in the filling valve

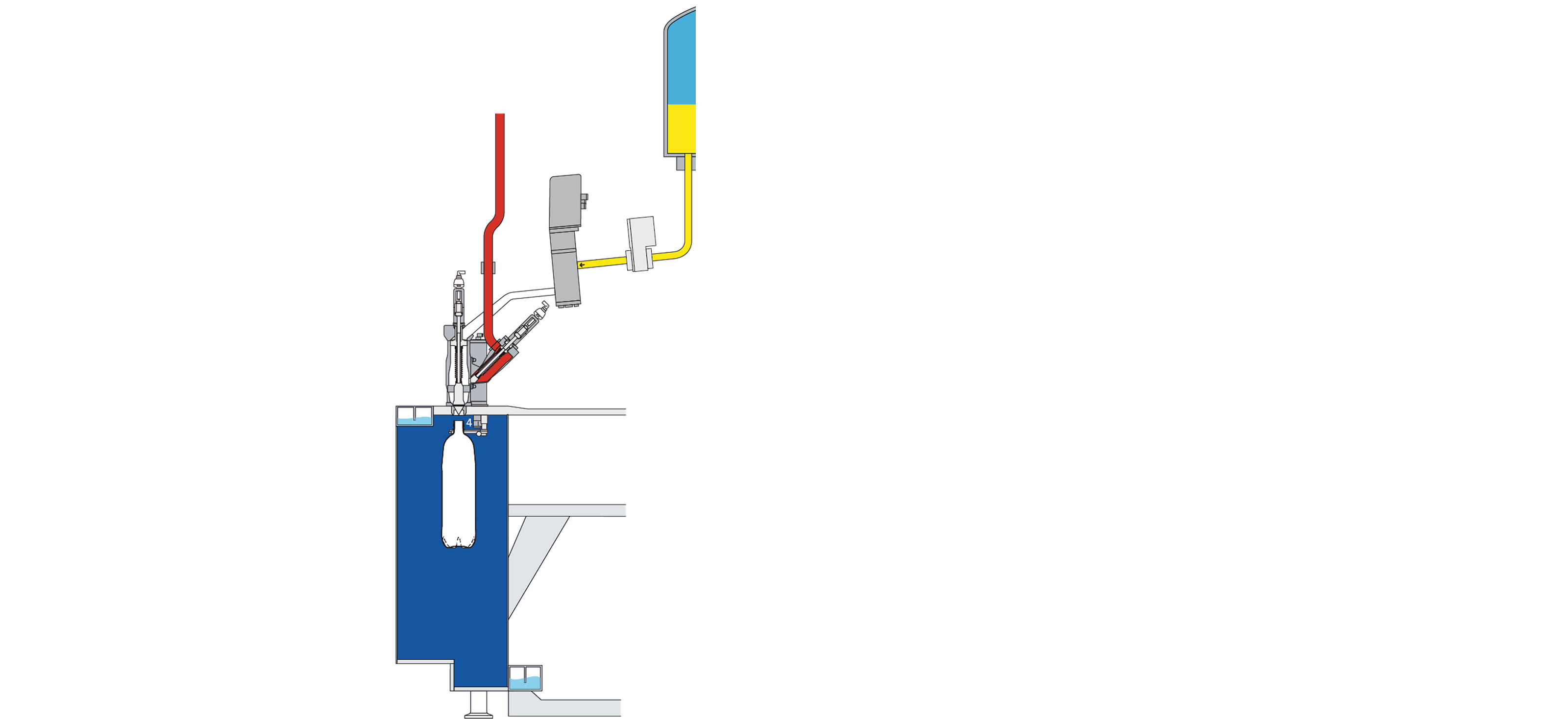

VFJ-D: Volumetric filling, Flow meter, full Jet, Double filling valve

PFR: Proportional Flow Regulator

Filling valve

Aseptic area

SIP cup

Hydraulic seal “Liquid seal system”

Valve stem

Dosing bevel control cylinder (particles)

Inductive flow meter

Pneumatic cylinder, valve stem

Particle pipe

PFR filling valve

Central bowl

Benefits to you

- High microbiological safety

- Optimum flow behaviour

- Smooth filling process which is gentle on the product

- Quick filling process without foaming

- Gentle treatment of the particles

- No pre-dosing unit needed

- Minimum product loss

- Quick and media-efficient disinfection

- No CIP distributor needed

- Flexible use for different products

- Very precise fill quantities

- No particle overdosing needed

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events