Lavatec R/LavaClassic D Head Rinser

The Head Rinser

The modular rinser has a pre-jetting, main treatment and a multi-stage post-treatment system.

Its modular design allows it to fulfil the most diverse and demanding customer requirements at the highest level.

At a glance

- Freely combinable, modular design

- Various post-treatment options, including special solutions such as hot discharge

- Separate caustic tank

- Modern servo drives

- Economical and responsible use of resources thanks to state-of-the-art technologies

- Meets your requirements at the highest level

- Output range: 5,000 to 120,000 bottles per hour

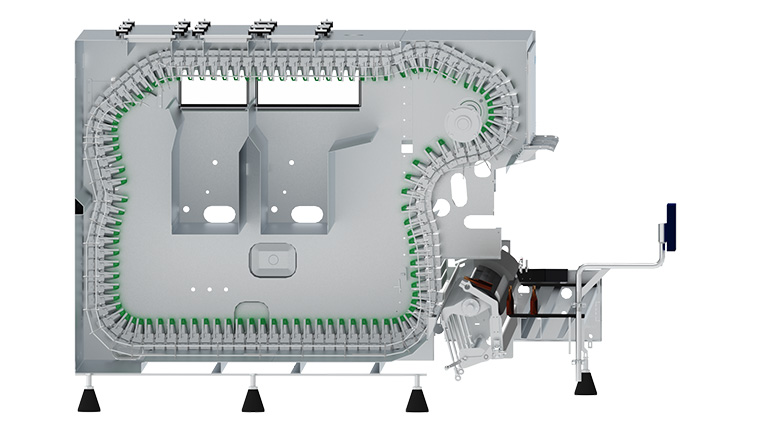

Lavatec R head rinser

Method of operation

- Regular cleaning of large quantities of bulk glass

- Bulk glass is visibly clean

- Light contamination can be easily removed

- Different forms of post-treatment can be achieved, e.g. hot discharge

- Servo drives

Benefits to you

- Reduced consumption of resources

- Establishment of microbiological safety

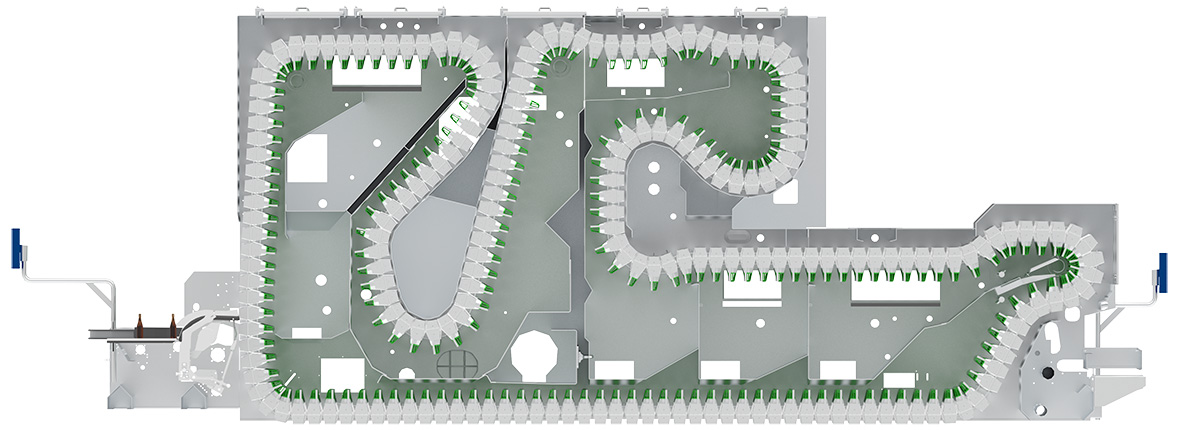

LavaClassic D head rinser

Method of operation

- Regular cleaning of large quantities of bulk glass

- Bulk glass is visibly clean

- Light contamination can be easily removed

- Different forms of post-treatment can be achieved, e.g. hot discharge

- Servo drives

Benefits to you

- Spatially separated infeed and discharge

- Reduced consumption of resources

- Establishment of microbiological safety

Benefits to you

Microbiologically up to date

The head rinsers are specialists in the cleaning of bulk glass. Visibly clean containers provide microbiological safety and meet the highest hygiene demands.

Absolutely efficient

Resources are used sparingly thanks to the latest technology. At the same time, the modular machine layout can be individually customised to suit the bottle quality.

Sparing use of resources

The Krones head rinser offers surprisingly economic water and energy consumption. And it proves that you do not always need lots of chemicals to achieve the highest hygiene standards.

Digitally up to date

The latest technology used on the touch-screen and in the PLC ideally equips our machines for the new age of digitalization. For this purpose, we offer a wide portfolio of digital products for the line and machine, as well as individual setting options directly on the touch-screen.

Operation made easy

All head rinsers offer easy access to all components so that cleaning and maintenance can be performed as quickly as possible.