Let’s start at the beginning: What is a life cycle assessment (LCA)? Generally speaking, it’s an analysis used to measure the environmental impact of a product, service or process across its entire life cycle – from the resources used to create the product or service, across its use phase, all the way through to its end-of-life destination (recycling or disposal).

Why do an LCA?

Like so many companies, Krones performs LCAs on its products and services because they are a valuable tool for …

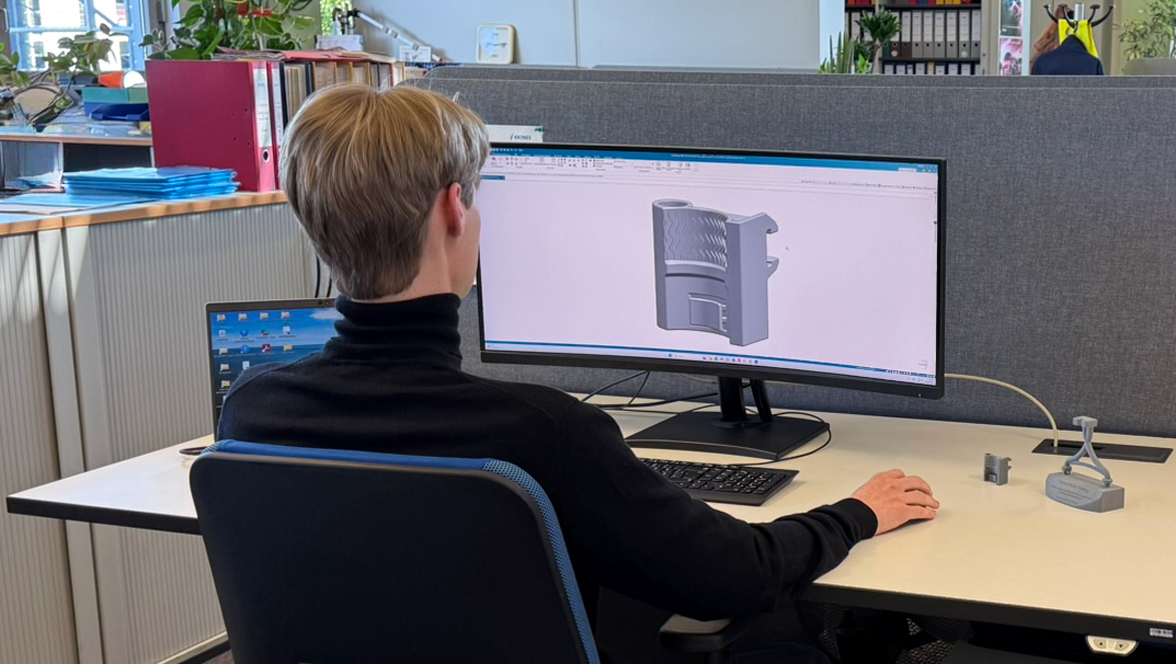

- Product development – to systematically reduce the environmental impacts of our machines and services and at the same time increase their efficiency.

- Our customers – to give them a solid set of data on which to base their investment decisions.

- Sustainability management – to

- measure and manage our progress towards achieving the goals laid out in Krones’ sustainability strategy and

- ensure compliance with legal requirements such as the EU Taxonomy and the digital product passport (DPP), which is slated to enter into force in the coming years.