Making it easier for customers to choose enviro

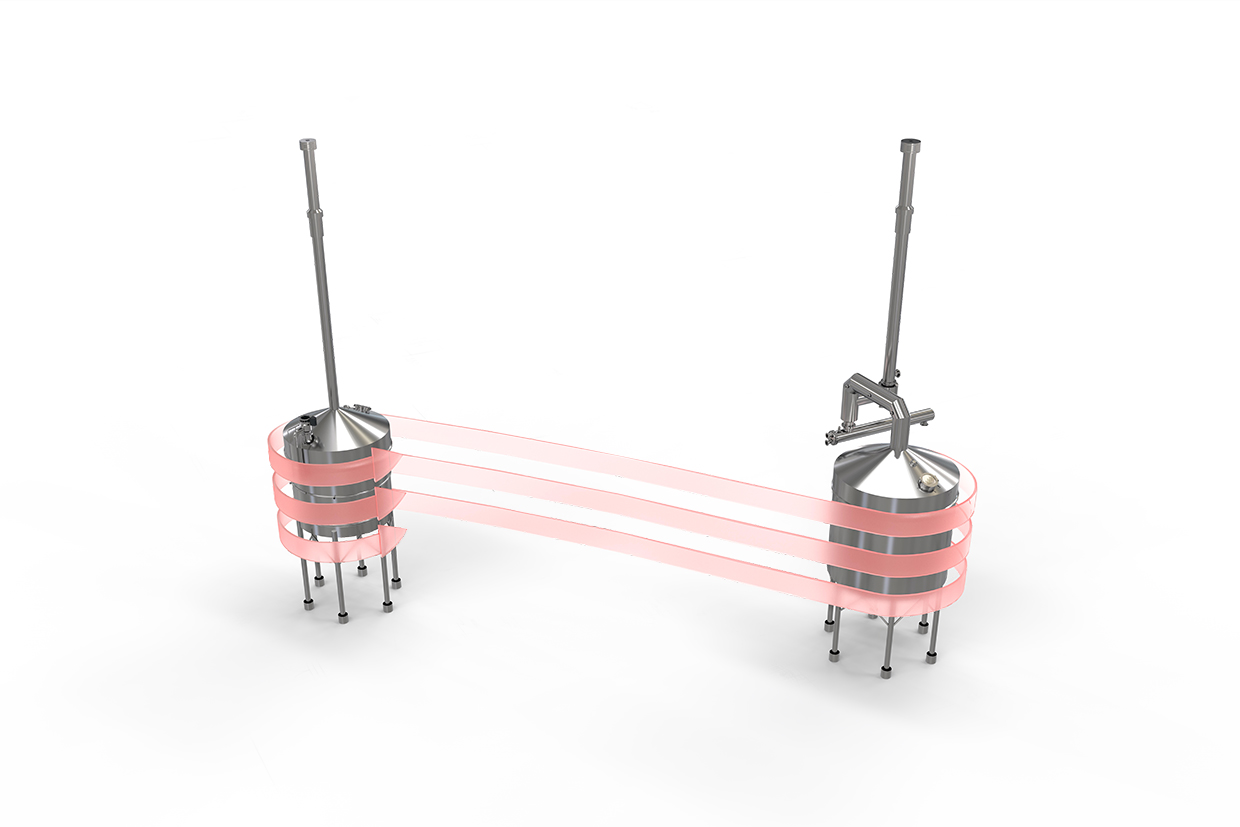

Under Krones’ climate goals, our group needs to reduce its greenhouse gas emissions in the upstream and downstream supply chains by 30 percent by 2030. The majority of these Scope 3 emissions are generated in the use phase of our products, at our customers’ plants. That means that enviro plays a crucial role in our group’s climate strategy. The more customers choose technologies with higher resource efficiency (thus permanently cutting their own carbon emissions), the more our Scope 3 emissions are reduced – which is ultimately good for the climate.

In order to make that choice as easy as possible for our customers, we have updated our bid preparation process. Customers inquiring about a solution from Krones will now receive a bid that includes a clear breakdown of the energy and media-efficient features we offer for each application. And in particular, what media and energy savings can be achieved. Unlike before, customers no longer need to actively ask for a resource-friendly solution. They simply receive a choice of suitable options right from the start as part of the proposal, perfectly transparently with a listing of the respective costs as well.

We want to significantly reduce our machines’ Scope 3 emissions. Including enviro in bids by default is one measure aimed at accomplishing that. Our goal is to show, in our bids, just what we are capable of in terms of sustainability and to engage with our customers on the topic. We want to offer them the best possible solution – one that helps them achieve their own emissions targets.

Christopher UrbanskyExpert for Product Sustainability at Krones

Christopher UrbanskyExpert for Product Sustainability at Krones